丰田汽车:精益模式的实践TOYOTA WAY FIELDBOOK

所售商品均为实拍,品相,册数已实拍为准。如有库存择优发货

¥ 160 6.3折 ¥ 255 九品

仅1件

送至北京市朝阳区

运费快递 ¥5.90

作者Jeffrey Liker 著

出版社Warner Books

出版时间2005-09

版次1

装帧平装

货号D11

上书时间2025-02-06

评价8660好评率 99.91%

- 最新上架

商品详情

- 品相描述:九品

图书标准信息

- 作者 Jeffrey Liker 著

- 出版社 Warner Books

- 出版时间 2005-09

- 版次 1

- ISBN 9780071448932

- 定价 255.00元

- 装帧 平装

- 开本 16开

- 纸张 胶版纸

- 页数 475页

- 【内容简介】

- The Toyota Way Fieldbook is a companion to the international bestseller The Toyota Way. The Toyota Way Fieldbook builds on the philosophical aspects of Toyota's operating systems by detailing the concepts and providing practical examples for application that leaders need to bring Toyota's success-proven practices to life in any organization. The Toyota Way Fieldbook will help other companies learn from Toyota and develop systems that fit their unique cultures.

- 【作者简介】

- JEFFREY K.LIKER, the author of the bestselling The Toyota Way, is Professor of Industrial and Operations Engineering and cofounder and Director of the Japan Technology Management Program at the University of Michigan. His work has appeared in The Harvard

- 【目录】

-

Acknowledgments

Foreword

Preface

Part Ⅰ Learning from Toyota

1.Background to the Fieldbook

Why The Toyota Way Fieldbook?

How the Book Is Organized

Overview of the Toyota Way Principles

How to Use This Book

Part Ⅱ Why Does Your Company Exist?

2.Define Your Corporate Philosophy and Begin to Live It

What Is Your Company's Philosophy?

A Sense of Purpose Inside and Out

Creating Your Philosophy

Living Your Philosophy

Making a Social Pact with Employees and Partners

Maintaining Continuity of Purpose

Part Ⅲ Creating Lean Processes Throughout Your Enterprise

3.Starting the Journey of Waste Reduction

Lean Means Eliminating Waste

Developing a Long-Term Philosophy of Waste Reduction

Value Stream Mapping Approach

Benefits of the Value Stream Mapping Approach

Developing a Current State Map

Understand Your Objectives When Mapping the Current State

Limitations of the Value Stream Mapping Approach

Creating Flow Step by Step

Sequential and Concurrent Continuous Improvement

4.Create Initial Process Stability

First Get to Basic Stability

Indicators of Instability

Clearing the Clouds

Objectives of Stability

Strategies to Create Stability

Identify and Eliminate Large Waste

Standing in the Circle Exercise

Standardized Work as a Tool to Identify and Eliminate Waste

5S and Workplace Organization

Consolidate Waste Activities to Capture Benefits

Improve Operational Availability

Reduce Variability by Isolating It

Level the Workload to Create a Foundation for

Flow and Standardization

5.Create Connected Process Flow

One-Piece Flow Is the Ideal Why Flow?

Less Is More: Reduce Waste by Controlling Overproduction

Strategies to Create Connected Process Flow

Single-Piece Flow

Key Criteria for Achieving Flow

Complex Flow Situations

Pull in a Custom Manufacturing Environment

Creating Pull Between Separate Operations

Flow, Pull, and Eliminate Waste

6.Establish Standardized Processes and Procedures

Is Standardization Coercive?

Standardized Work or Work Standards?

Objective of Standardization

Strategies to Establish Standardized Processes and Procedures

……

7.Leveling:Be More Like the Tortoise Than the Hare

8.Build a Culture That Stops to Fix Problems

9.Make Technology Fit with People and Lean Processes

Part Ⅳ Develop Exceptional People and Partners

10.Develop Leaders Who Live Your System and Culture from Top to Bottom

11.Develop Exceptional Team Associates

12.Develop Suppliers and Partners as Extensions of the Enterprise

Part Ⅴ Root Cause Problem Solving for Continuous Learning

13.Problem Solving the Toyota Way

14.Develop a Thorough Understanding of the Situation and Define the Problem

15.Complete a Thorough Root Cause Analysis

16.Consider Alternative Solutions While Building Consensus

17.Plan-DO-Check-Act

18.Telling the Story Using an A3 Report

Part Ⅵ Managing the Change

19.Lean Implementation Strategies and Tactics

20.Leading the Change

Index

相关推荐

为你推荐

当代中国经典美术片书系——大闹天宫

八五品衡水

¥3.00

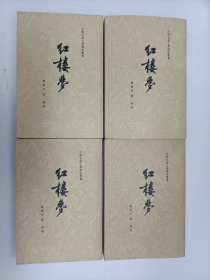

红楼梦

九品深圳

¥2400.00

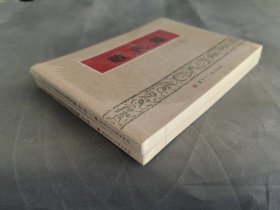

清,薜氏医案

九五品邢台

¥200000.00

中医古籍整理丛书:20本合售,疫疹一得,伤寒论校注,难经校注,活人书,温疫论补注,难经本义,难经语译,研经言,明医杂著,痘疹辨证,脉经语译,明目至宝,圣济经,伤寒辨证,伤寒论语译,中藏经语译,中藏经校注,金匮玉函经二注,金匮要略论注,金匮要略校注,全部是一版一印,内未翻阅过

八五品北京

¥6666.00

浙江传媒学院校友录

九品济宁

¥48.00

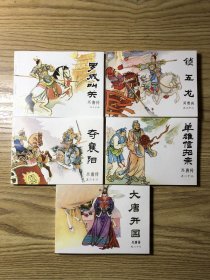

兴唐传五大缺:《罗成叫关》《锁五龙》《夺襄阳》《单雄信招亲》《大唐开国》(非34册全套,其余29册已经售出)黄纸印刷,有钉装也有线装。1985年一版一印。中国曲艺出版社出版的连环画《兴唐传》虽未曾获过奖,但并不影响其艺术价值和至今仍具有的广泛影响力 ,由23位中青年画家历时五年完成,以线描国画技法绘制,人物造型、服饰、兵器等统一,绘画细腻传神,对隋唐时期的人物场景等刻画细致。

九五品湖州

¥12000.00

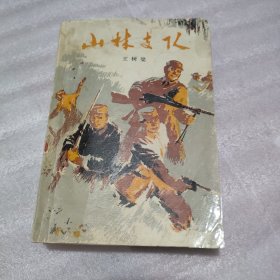

山林支队<上

八五品北京

¥8.00

毛泽东选集合订一卷本

九品石家庄

¥1680.00

鲁迅曾把家藏的一部24册的书,全部钞了一遍:这就是元和顾之逵辑《艺苑捃华》秘书四十八种,24册全。同治年刻~

七五品北京

¥12000.00

连环画

全新郑州

¥5.00

小北斗村

八品石家庄

¥3.00

列宁选集(全四卷)

八五品杭州

¥45.00

萨克斯,上海牌,1954年,编号67519,仅存孤品,收藏价值高,可开发票。

八五品武汉

¥8600.00

古拉格群岛

九品北京

¥399.00

《毛泽东选集》第四卷

八五品上海

¥28.88

红楼梦 上海古籍出版社

八品重庆

¥16.00

西游记(上中下册缺中)

八品北京

¥10.00

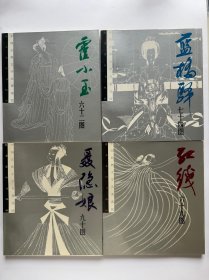

《蓝桥驿七十四图》 《红线六十九图》 《聂隐娘九十图》 《霍小玉六十二图》

九五品广州

¥4200.00

让孩子越看越聪明的365个智慧故事:老苹果树

八五品济南

¥2.00

朗读手册:大声为孩子读书吧

九品北京

¥58.80

— 没有更多了 —

微信扫码逛孔网

无需下载

书里的故事精美,还赠送贴纸,很不赖

成色还可以