视觉传感及其应用:激光传感器与工业机器人的结合(英文版)

¥ 40 3.3折 ¥ 120 九品

仅1件

送至北京市朝阳区

运费快递 ¥8.00

作者甘中学、汤青 编

出版社浙江大学出版社

出版时间2011-05

版次1

装帧精装

货号1架3-3A

上书时间2025-03-23

评价1446好评率 100%

- 店主推荐

- 最新上架

商品详情

- 品相描述:九品

- 书品如图,以图为准,实图拍照,看图下单

图书标准信息

- 作者 甘中学、汤青 编

- 出版社 浙江大学出版社

- 出版时间 2011-05

- 版次 1

- ISBN 9787308080514

- 定价 120.00元

- 装帧 精装

- 开本 16开

- 纸张 胶版纸

- 页数 259页

- 字数 423千字

- 正文语种 英语

- 【内容简介】

- VisualSensinganditsApplicationsIntegrationofLaserSensorstoIndustrialRobotsprovidescomprehensiveandup-to-datecoverageofresearchanddevelopmentonthisroboticvisionsystem.Alaser-structuredlightisthemainconcernindiscussionsofvisualsensing.Alsoaddressedinthisbookareallcomponentsoftheroboticvisionsystemandanemphasisonhowtoincreasetheaccuracyofthesystemusingthreelevelsofcalibration.Thisincludescalibrationofthevisionsystem(eyecalibration),calibrationofeye-to-handconfigurationandcalibrationofrobotkinematics(handcalibration).Withtheintegrationofthelasersensorstoindustrialrobotsnumerousapplicationsinthefieldofroboticwelding,grinding,machining,inspection,andpalletiz-ingareillustratedbasedonpracticalengineeringprojectsinordertodemonstratehowthevisualsensingisperformed.Thebookwillserveasavaluableresourceforresearchersandengineersintheareasofroboticsandmachinevision.

- 【目录】

-

1Introduction

1.13DAcquisitionTechniques

1.1.12DVision

1.1.2StereoVision

1.1.3TimeofFlight

1.1.4LaserTriangulationSensor

1.2StructureofRobotVisualControlSystem

1.2.1Structured-LightSensorBasedVisualControl

1.2.2SelectionofIndustrialRobots

1.2.3ApplicationsofRobotVisualSystems

1.2.4CalibrationofRobotVisualSystems

1.2.5LaserSensorBasedCommercialRobotVisualSystems

1.3OutlineofChapters

References

2CharacteristicsofLaserStructured-LightSensors

2.1FormationofLaserStructured-LightSensors

2.1.1LightSource

2.1.2DetectorTypes

2.1.3TriangulationMeasurementPrinciple

2.2AccuracyAnalysis

2.2.1EffectofLaserSpeckleNoiseontheMeasurement

Accuracy

2.2.2EffectoftheEnvironmentalFactorsontheMeasurement

Accuracy

2.3CommercialSystems

References

3LaserStripeSensorCalibration

3.1ModelingofLaserStripeSensorandCalibrationStrategy

3.2CameraModeling

3.2.1PinholeModeloftheCamera

3.2.2NonlinearModelingwithLensDistortion

3.3CalibrationofCameras

3.3.1CalibrationwithDirectLinearTransformMethod

3.3.2CalibrationwithTsai'sRACBasedAlgorithm

3.3.3CalibrationwithMultipleViewAlgorithms

3.4CalibrationofLaserStripeSensor

3.4.1LaserStripePlaneCalibrationwithTwoKnownPlanes

3.4.2LaserStripePlaneCalibrationBasedonInvarianceofCrossRatios

3.4.3LaserPlaneCalibrationwithaPlanarTarget

3.4.4CalibrationofDualLaserStripeSensor

3.4.5CalibrationoftheRotationTable

3.4.6CalibrationoftheLaserStripeSensorwithRobotAlignment

3.4.7LaserScannerCalibrationwithDirectCoordinateMapping

3.4.8CalibrationofLaserStripeSensorwithScheimpflugConfiguration

3.5ConclusionandRemarks

References

CalibrationofaRobotVisualSystem

4.1GeneralSolutionofRobotToolCalibration

4.1.1CalibrationTargetwithGeometryConstraint:Point

4.1.2CalibrationTargetwithGeometryConstraint:Line

4.1.3CalibrationTargetwithGeometryConstraint:Sphere

4.1.4CalibrationTargetwithGeometryConstraint:Plane

4.2TCPCalibrationforaPointLaser

4.2.1Algorithms

4.2.2CalibrationofLaserBeamOrientation(nx,ny,nz)

4.2.3CalibrationofLaserSensorPosition(x0,Y0,z0)

4.2.4ExperimentalResults

4.3TCPCalibrationforCameras

4.3.1CameraPoseCalibrationwithLinearEquations

4.3.2CameraPoseCalibrationwithNonlinearOptimizations

4.4TCPCalibrationfor3DLaserScanner

4.4.1TCPCalibrationwithaSphere

4.4.2TCPCalibrationwithaPlane

4.4.3TCPCalibrationwithaStructurePattern

4.5TCPCalibrationwithDirectMeasurement

4.5.1CalibrationofSpindle

4.5.2CalibrationofToolswithDifferentLength

4.6RelativeRobotWorkcellCalibration

4.6.1RobotWorkcellCalibration

4.6.2RobotErrorCompensationwithRelativeMeasurement

4.7Summary

References

5ImageProcessingofLaserStructured-LightBasedVisionSystem

5.1ControlPointExtractionfromPatternImages

5.1.1FeatureExtractionfromSquaredControlPoints

5.1.2FeatureExtractionfromCircleControlPoints

5.2LaserStripeSub-PixelPositioning

5.2.1ThinningandPruningAlgorithm

5.2.2GrayScaleGravityCenterAlgorithm

5.3RangeImageRegistrationwiththeICPAlgorithm

5.3.1DeterminationofCorrespondingPoints

5.3.2CalculationofTransformationMatrix

References

6RobotKinematicCalibration

6.1Background

6.2ModelFunctionofRobots

6.3DeterminationofIndependentErrorParametersUsingSVDMethod

6.4ErrorBudgetAnalysis

6.5SolvingtheErrorParameters

6.6CircleFittingBasedCalibration

6.7TAUParallelRobotCalibration

6.7.1KinematicModeling

6.7.2JacobianMatrixofTAURobotwithAllErrorParameters..

6.7.3KinematicModelingwithallErrorParameters

6.7.4DeterminationofIndependentDesignVariables

6.7.5ErrorBudgetAnalysis

6.7.6SimulationResults

6.7.7ExperimentalResults

References

7VisualSensingandControl-LaserSensorBasedRobotApplications..

7.1AutomaticInspectionofHolesin3DSpace

7.1.1Introduction

7.1.2SystemOverview

7.1.3SystemCalibrations

7.1.4InspectionProcedure

7.1.5ExperimentalResultsandConclusion

7.2RoboticGrindingSystemofFree-FormWorkpieces

7.2.1Introduction

7.2.2OffiineProgramming

7.2.3WorkpieceCalibration

7.2.4RoboticSystemErrorCompensation

7.2.5ExperimentalSystem

7.2.6ConclusionandRemarks

7.3RobotRemanufacturingofBladeTipRefurbishment

7.3.1Introduction

7.3.2ProfileModelingBasedGrinding

7.3.3ExperimentalSetup

7.3.4ConclusionandFutureWork

7.4RoboticMaterialsHandlingSystemforComplexParts

7.4.1SystemOverview

7.4.2ApproximatelyLocatiogWorkpieces

7.4.3PreciselyLocatingWorkpieces

7.4.4AnotherExample

7.4.5SummaryandRemarks

7.5RobotMachiningSystemwithVisualFeedback

7.5.1Introduction

7.5.2SystemOverview

7.5.3ScanningandEdgeDetection

7.5.4PathSmoothingBasedontheB-Spline

7.5.5OtherExamples

7.5.6SummaryandRemarks

7.6RoboticMeasurementandInspectionSystemforQualityControl

7.6.1SystemOverview

7.6.2Pick-upErrorCompensation

7.6.3FeatureBasedWorkpieceLocationing

7.6.4PointCloudComparison

7.6.5SummayandRemarks

7.7RobotWeldSystemwithSeamTrackingSensors

7.7.1SystemOverview

7.7.2WeldingJointDetection

7.7.3PathGeneration

7.7.4Computer-RobotCommunication

7.7.5ARoboticTubePanelWeldSystem

7.7.6SummaryandRemarks

7.8RoboticPickandPlaceSystemwithPointLasers

7.8.1RobotLogsPickandCenterSystem

7.8.2RobotSolarPanelInstallationSystem

7.8.3SummaryandRemarks

References

Appendix

Index

- 配送说明

北京发货-只发快递,不发邮政。实图拍照看图下单。

为你推荐

毛泽东选集 封面头像一卷本

八五品西安

¥398.00

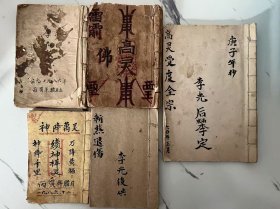

B7900 罕见湖南《高灵教法本》五部共238筒子页,有完整的传度与水法治病,符型与兵马的运用都很独特(有专门的养兵马符),五花洲(可能在益阳)起教,祖师李君法显公伯文将军生于康熙十七年死于乾隆廿七年,廿十六岁任湖南宝庆府府长,三十九岁辞官回乡行教。历代祖师姓名生庚等信息记录很完整,最难得的是书的出处记录很清楚,八十年代还有完整的传承,估计现在当地还有流传。

八品广州

¥15000.00

正版✔万有引力书系 长辈的故事 一部映照20世纪华夏大地栉风沐雨的家族记忆史 两大家族的命运沉浮 一个民族的百年变局 留下长辈的故事 比留下他们 熊景明✍王鼎钧、陈方正、林超民、林达、唐小兵诚挚推荐!两大家族的命运沉浮,一个民族的百年变局;留下长辈的故事,比留下他们的骨灰更有意义正版全新稀缺好书现货如需其他图书敬请联系客服:)

全新上海

¥43.10

青少年网络素养读本:网络游戏与网络沉迷

九五品成都

¥4.10

毛主席语录 完整一册:(极品收藏:1963年沈阳空军初版,近10品,50开本,红色漆布封皮,精装本,对照白纸普及本,内容完全一样,无年代字样)

九五品北京

¥380000.00

读报手册 封面漂亮

八五品南京

¥80.00

金瓶梅

九五品武汉

¥520.00

云海玉弓缘

八五品中山

¥8.88

文教政策

七品昆明

¥498.00

广东儿童 1980年第3、5、10、11期(合售)

八品南阳

¥18.00

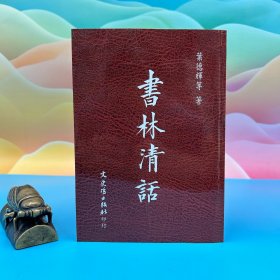

台湾文史哲版 叶德辉等《书林清话》1988年版

全新北京

¥206.00

Python网络爬虫基础教程

八五品重庆

¥2.00

毛泽东选集·全四卷(67年上海一版二印)

八品上海

¥320.00

问卷数据分析――破解SPSS的六类分析思路

九品北京

¥10.00

原版旧书民间六爻学

八五品盐城

¥50.00

评点本金庸武侠鹿鼎记:4本合售

九品上海

¥30.00

毛泽东选集(白皮1---4卷)

八品武汉

¥180.00

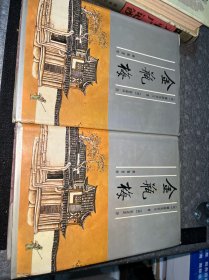

永庆升平后传

八五品成都

¥40.00

企鹅经典

九品沧州

¥688.60

红书

九品保定

¥70.00

— 没有更多了 —

微信扫码逛孔网

无需下载

![Wonders Literature Anthology《G1-U1/1-6》6本 +Wonders Reading/Writing《G1-U1/1-6》6本+wonders Reading/Writing workshop 《Unit1-10》10本+Wonders 《Grade1》2本+Wonders〈3、6〉2本+Your Turn《9、10》2本+Start Smart1本[共29本合售]](https://www0.kfzimg.com/sw/kfzimg/1798/01601b0302abf380f3_s.jpg)

收到了,品相尚可。😘

书保存的很好